-

the effects of rotational and traveling speeds on grain size, cavities and precipitations of sic-az31 nano-composites fabricated via fsw method

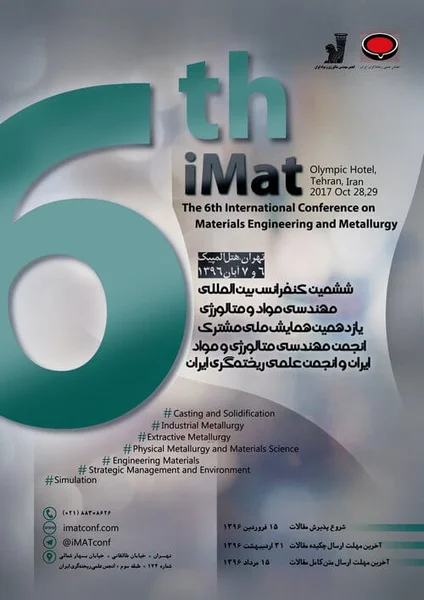

جزئیات بیشتر مقاله- تاریخ ارائه: 1396/07/11

- تاریخ انتشار در تی پی بین: 1396/07/11

- تعداد بازدید: 447

- تعداد پرسش و پاسخ ها: 0

- شماره تماس دبیرخانه رویداد: -

the solid-state nature of the friction stir welding (fsw) process leads to several advantages over fusion welding methods as problems associated with cooling from the liquid phase are avoided. in this study, friction stir welding (fsw) technique was employed for joining az31 magnesium plates. since sic particles had been injected along the joint line, az31/sic nano-composite was developed in the stir zone (sz) and the effects of rotational and traveling speeds on grain size, cavities and precipitations of stir zone were investigated. three rotational speeds 600,800, 1000 round per minute and four traveling speeds 25, 75, 125 and 175 millimeter per minute were used for welding of specimens. microstructural studies showed that increase of traveling and rotational speeds, generally deceased grain size of composites. also, cavities and al3mn precipitations were identified as main precipitations of composite. due to apply plastic deformation during fsw, magnesium grains at tmaz were observed in long shape. moreover, al3mn precipitations at tmaz were finer than those at bm.

مقالات جدیدترین رویدادها

-

استفاده از تحلیل اهمیت-عملکرد در ارائه الگوی مدیریت خلاقیت سازمانی و ارائه راهکار جهت بهبود

-

بررسی تاثیر ارزش وجوه نقد مازاد بر ساختار سرمایه شرکت های پذیرفته شده در بورس اوراق بهادار تهران

-

بررسی تأثیر سطح افشای ریسک بر قرارداد بدهی شرکت های پذیرفته شده در بورس اوراق بهادار تهران

-

بررسی تأثیر رتبه بندی اعتباری مبتنی بر مدل امتیاز بازار نوظهور بر نقد شوندگی سهام با تأکید بر خصوصی سازی شرکت ها

-

تأثیر آمیخته بازاریابی پوشاک ایرانی بر تصویر ذهنی مشتری پوشاک ایرانی (هاکوپیان)

-

تاثیر نوع استراتژی و توانمندی های سازمانی بر عملکرد: نقش میانجی تکنیک های حسابداری مدیریت

-

ارزیابی توزیع فضایی بافت فرسوده در شهر آبدانان و ارائه الگوی بهینه مداخله در آن

-

مدل سازی استاتیک مخزن دالان در یکی از میادین جنوب ایران

-

تعیین پارامتر های موثر در حمل و نقل مطلوب شهری با استفاده از روش ahp نمونه موردی شهر شیراز

-

سیرالولیاء؛ مستندترین تذکره در شرح احوال مشایخ سلسله چشتیه

مقالات جدیدترین ژورنال ها

-

مدیریت و بررسی افسردگی دانش آموزان دختر مقطع متوسطه دوم در دروان کرونا در شهرستان دزفول

-

مدیریت و بررسی خرد سیاسی در اندیشه ی فردوسی در ادب ایران

-

واکاوی و مدیریت توصیفی قلمدان(جاکلیدی)ضریح در موزه آستان قدس رضوی

-

بررسی تاثیر خلاقیت، دانش و انگیزه کارکنان بر پیشنهادات نوآورانه کارکنان ( مورد مطالعه: هتل های 3 و 4 ستاره استان کرمان)

-

بررسی تاثیر کیفیت سیستم های اطلاعاتی بر تصمیم گیری موفق در شرکتهای تولیدی استان اصفهان (مورد مطالعه: مدیران شرکتهای تولیدی استان اصفهان)

-

صنعت خودروی تجاری ایران از منظر بازگران: راهکارهایی برای توسعه

-

بررسی تاثیر وابستگی به گروه تجاری بر انتخاب حسابرس

-

واکاوی تهدیدها و فرصت های جذب سرمایه گذاری در صنعت پتروشیمی از دیدگاه کارکنان شپترو

-

the management of capital assets life cycle in petrochemical industry

-

influence of polypropylene length on stability and flow of fiber-reinforced asphalt mixtures

سوال خود را در مورد این مقاله مطرح نمایید :